Out of the five 3-D prints, I printed four. This consisted of being at the door of the FabLed before it opened to get a printer, fixing the prints, changing the material in the machine, ensuring the 3-d models printed correctly, and everything was in scale. Overall any time I would go to print it would take me the morning to do so. And the night before to be have everything prepared and perfect for printing. I always tried to print on a Friday as prints could take from 24 – 48 hrs.

Out of all the materials to select I went with picking translucent. At the time we hadn’t decided if we where going to paint the models or just keep them one colour. When printing I had hoped that if I choose translucent that our coloured light would be able to shine through it.

I also had the task of figuring out the measurements for what each of the 15 3-d models would be. To have them at a size that they would sit nicely and in scale on each podium, I found the easiest way to do this was by have an outline of the podium on paper and then drawing the base of the 3-d model width on it to see what looked best.

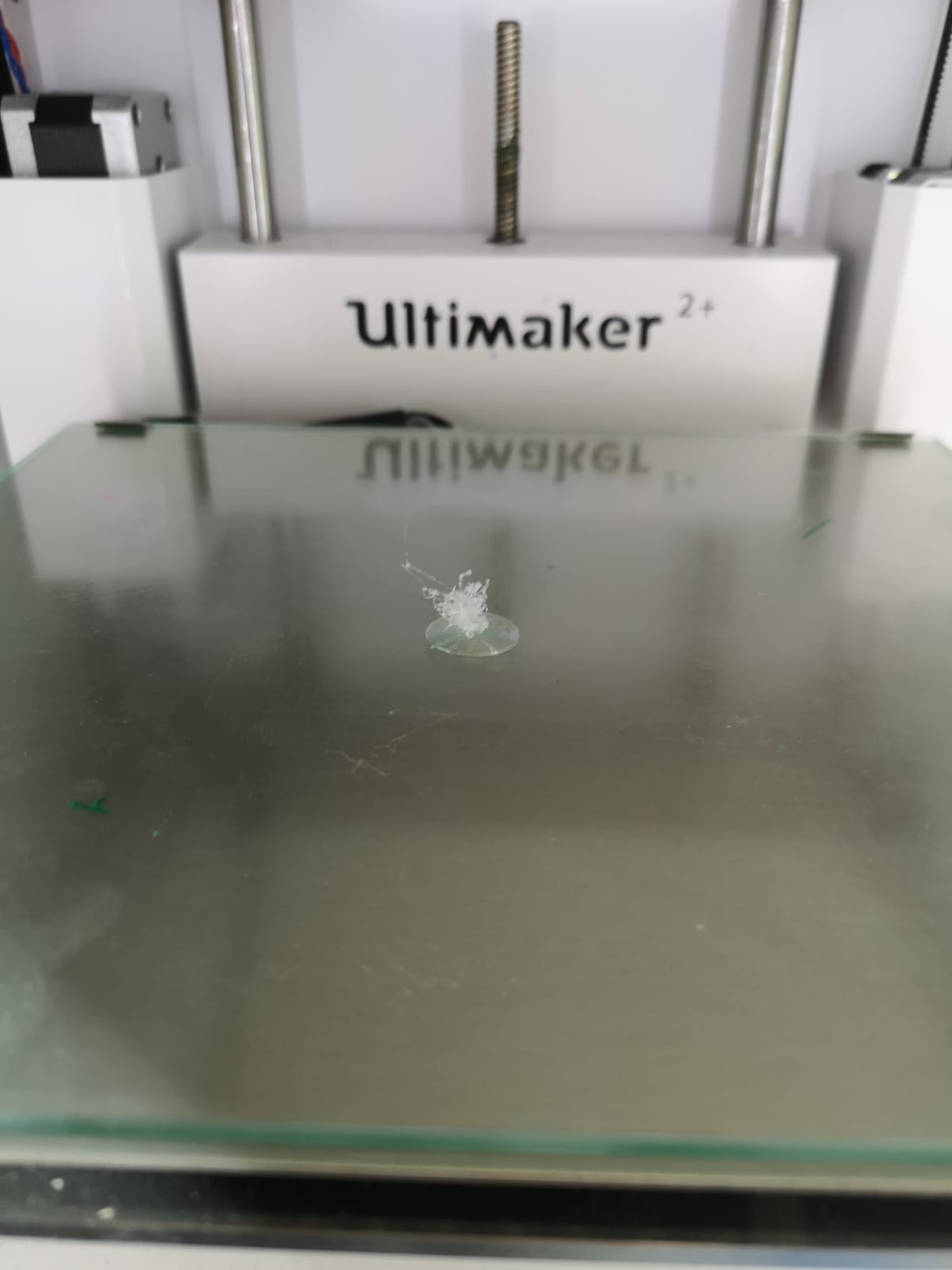

Working with 3-d printing was a new experience. It was an amazing to see Ibrahim and my designs to come to life. There was even one morning which I spent 3 hours trying to print and nothing would work out.This was disheartening, so I focused on college for the rest of the day and the next morning tried again. It did require patience, many times there where no free printer or there was no translucent material, or the translucent material was running out. Or that the prints when put through cura where not fully there. Meaning I would have to rebuild or fix them. This made me be more cautious of my use of material, even resulting in me cutting and inly printing small parts that could be stuck on previous fail print that could save material. But in the end it all worked out. I would collect the prints and take the majority of the support material off and the guys would clean the fine detail.